Our Lab Facilities

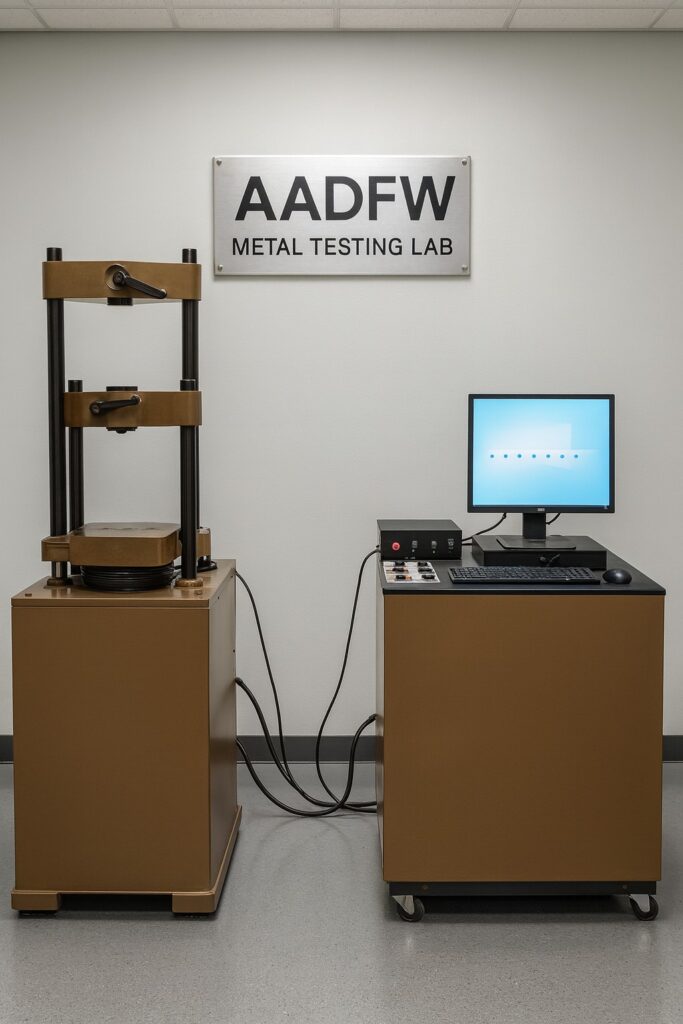

AADFW Testing Facilities

In addition to our skilled team of certified testers and engineers, our lab is equipped with the top-level equipment required by professionals in the aerospace and oil and gas industry. We also created custom systems to meet our clients needs. Here are some of the machines we use to assist our clients in testing their top-tier products and designs.

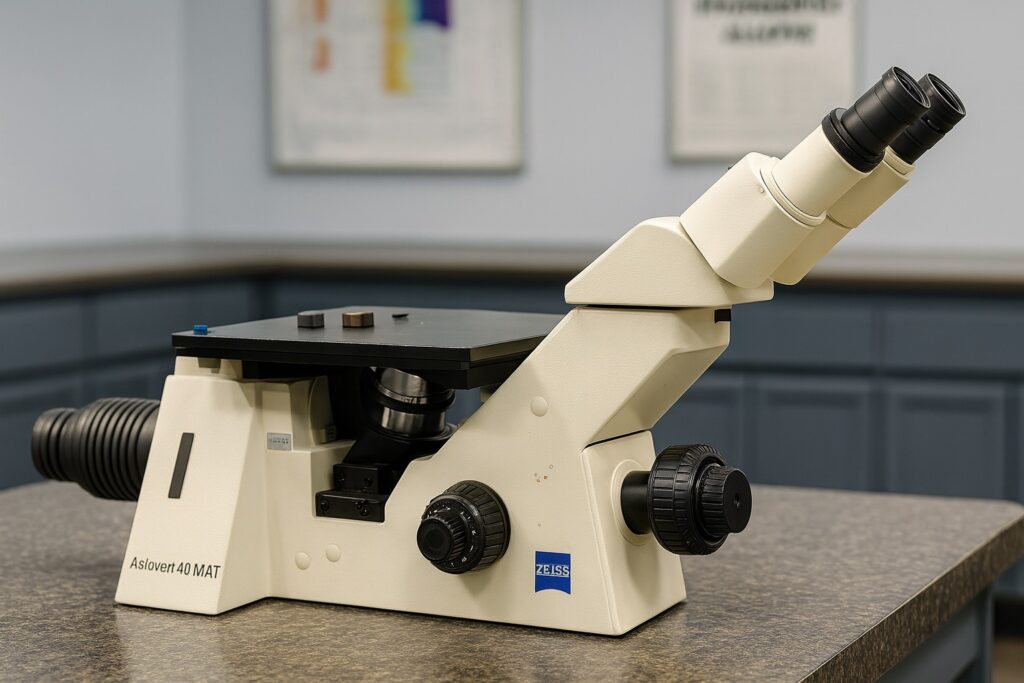

Zeiss Metallurgic Microscope

AADFW has several of these instruments for metal tests. This system provides high-precision imaging for detailed microstructural evaluation, enabling grain size analysis, inclusion rating, weld inspection, and metallurgical failure investigation. Its advanced optics and digital measurement capabilities ensure accurate characterization of critical aerospace and oil & gas materials.

Mitutoyo HR 530

Used for precise hardness measurement across a range of metallic materials using Rockwell, Superficial Rockwell. Its high-accuracy load application and digital depth-measurement capabilities ensure reliable evaluation of material strength, surface condition, and heat-treat response for aerospace and oil & gas applications.

Clark Micro-Hardness Machine

This system performs accurate hardness measurement using Rockwell and Superficial Rockwell methods to evaluate metallic material strength and surface condition. Its controlled load application and precision depth-reading capabilities provide reliable assessment of heat-treated components and critical aerospace and oil & gas alloys.

Brinell Hardness Machine

AADFW has two of these systems for testing of materials, typically used in the oil & gas industry. This system performs controlled Brinell hardness testing to evaluate material strength, surface condition, and heat-treat response across a wide range of alloys. Its calibrated load application and optical measurement capabilities provide reliable assessment of indentation diameter, ensuring consistent hardness values.

EDM Machine

With multiple EDM machines in the lab, AADFW uses these to provide controlled electrical-discharge machining to section metallic test coupons with high dimensional accuracy and minimal thermal distortion. It enables precise sample preparation for hardness testing, microstructural evaluation, and metallurgical analysis across a wide range of alloys. The machine’s stable discharge parameters and fine control of cut geometry ensure repeatable results suitable for critical aerospace and oil & gas materials. Its non-contact cutting process preserves material integrity, supporting reliable downstream evaluation.

Thermo Scientific Furnace

A scientific furnace provides controlled high-temperature processing for heat-treat evaluation, metallurgical conditioning, and sample preparation across a wide range of alloys. Its stable thermal profiles and precise temperature regulation enable reliable assessment of material response during annealing, tempering, and stress-relief procedures. Uniform chamber heating ensures consistent test conditions for aerospace and oil & gas materials. The furnace’s repeatable thermal performance supports accurate downstream hardness testing and microstructural analysis.

G8 Galileo

The G8 performs high-precision gas analysis to determine oxygen, nitrogen, and hydrogen content in metallic materials. Its controlled fusion and detection processes generate accurate compositional data essential for evaluating alloy cleanliness and processing quality. The instrument’s repeatable measurement capability supports material qualification requirements across aerospace and oil & gas applications.

Bruker OES Instrument

Optical emission spectroscopy is used to generate precise elemental analysis for ferrous and nonferrous alloys, supporting both routine quality checks and detailed material certification. Controlled spark excitation paired with a high-resolution spectrometer delivers accurate detection of alloying elements and trace impurities. AADFW uses their two OES systems to conduct repeatable analytical performance ensures dependable verification of chemistry requirements for aerospace and oil & gas applications.

Icarus Instrument

Icarus analysis enables precise determination of carbon and sulfur content in metallic materials using controlled combustion and high-sensitivity detection. The instrument delivers stable, repeatable measurements essential for assessing alloy cleanliness, heat-lot consistency, and processing quality. Its analytical accuracy supports material qualification and compliance requirements across aerospace and oil & gas applications.

Tensile Testing Machine

Tensile testing provides precise measurement of yield strength, ultimate tensile strength, elongation, and reduction of area for metallic materials. Controlled loading and high-resolution extensometry enable accurate characterization of mechanical performance across a wide range of alloys. These results give engineers definitive data for validating material suitability in demanding aerospace and oil & gas environments.

Tinius Olsen Machine

Tinius Olsen testing provides controlled Charpy testing. Working in conjunction with the Charpy chillers for determining mechanical properties of metallic materials. High-accuracy load cells and extensometry support precise measurement of strength, ductility, and deformation behavior across various alloy systems. Its capability to characterize material response under multiple loading modes makes it a critical tool in AADFW’s qualification workflow for aerospace and oil & gas components.

Bend Testing Machine

Bend testing evaluates ductility, fracture behavior, and surface integrity by applying controlled deformation to metallic specimens. Precision fixtures and regulated loading enable accurate measurement of bend angle, crack initiation, and material compliance with applicable standards. The resulting data provides a clear understanding of structural reliability for components used in aerospace and oil & gas operations.

Low-Temperature Bath Charpy Impact Tester

The low-temperature bath provides controlled sub-ambient conditioning of Charpy specimens to evaluate impact toughness under standardized test temperatures. Stable cooling profiles and precise thermal regulation ensure accurate assessment of material behavior at brittle-transition and service-relevant temperature ranges. By enabling consistent specimen conditioning, the bath plays a critical role in determining the suitability of alloys for low-temperature aerospace and oil & gas environments.

CNC Machines

CNC machining provides accurate shaping and dimensional refinement of test specimens through programmable cutting, milling, and contouring operations. The equipment’s controlled tool paths and stable spindle performance support tight-tolerance preparation for mechanical, metallurgical, and hardness evaluations. Its versatility in producing consistent geometries enhances AADFW’s ability to generate reliable test-ready samples across diverse alloy systems.

Do All Saws

Metal cutting operations produce controlled sectioning of metallic specimens for mechanical testing, metallography, and hardness evaluation. The machine’s regulated feed rates, coolant delivery, and abrasive or saw-blade configurations help maintain dimensional accuracy while minimizing thermal or mechanical alteration of the material. Its ability to generate clean, consistent cuts directly supports AADFW’s requirement for stable and repeatable test specimen preparation. Using multiple Do All saws and three Hem saws, samples are made ready for testing.

Salt Spray Chamber

Salt spray exposure testing evaluates corrosion resistance by subjecting metallic specimens to a controlled saline fog environment. Executing on the ASTM B117 methodology for corrosion tests. Precise regulation of temperature, spray concentration, and chamber humidity ensures consistent conditions for assessing coating performance and material durability. The chamber’s ability to reproduce accelerated corrosive environments provides critical insight into long-term service behavior for aerospace and oil & gas components.

Liquid Penetrant Testing Line

Liquid penetrant inspection is used to detect surface-breaking discontinuities in metallic components by applying controlled cleaning, penetrant, dwell, and developer stages. AADFW has several penetrant testing areas so multiple tests can be conducted at once. The line’s regulated processing parameters support accurate identification of cracks, laps, porosity, and other discontinuities across a wide range of alloys. Its consistent inspection workflow ensures dependable surface integrity evaluation for components prepared for aerospace and oil & gas service conditions.

Mag Particle Bench

Magnetic particle inspection identifies surface and near-surface discontinuities in ferromagnetic materials by applying controlled magnetization and particulate indication methods. The machine’s regulated field strength and precise particle application enable accurate detection of cracks, laps, seams, and other defect conditions. Its capability to reveal subtle flaw indications enhances AADFW’s reliability assessments for components used in aerospace and oil & gas applications.

Hydrogen Embrittlement Testers

Hydrogen embrittlement testing evaluates delayed fracture susceptibility in plated or high-strength metallic components under controlled load and environmental conditions. The equipment maintains stable stress application and monitored exposure periods to identify time-to-failure behavior and assess compliance with critical material performance requirements. Its ability to reveal hydrogen-induced degradation provides essential validation for components intended for demanding aerospace and oil & gas service environments.

Instron Tensile Frame

Instron testing provides controlled tensile, compression, and fastener tensile evaluation to characterize mechanical performance across a range of metallic materials. High-precision load cells and extensometry support accurate measurement of strength, deformation, and failure behavior under standardized test conditions. Its capability to generate dependable multi-mode mechanical data makes the frame a key asset in AADFW’s qualification and verification processes.

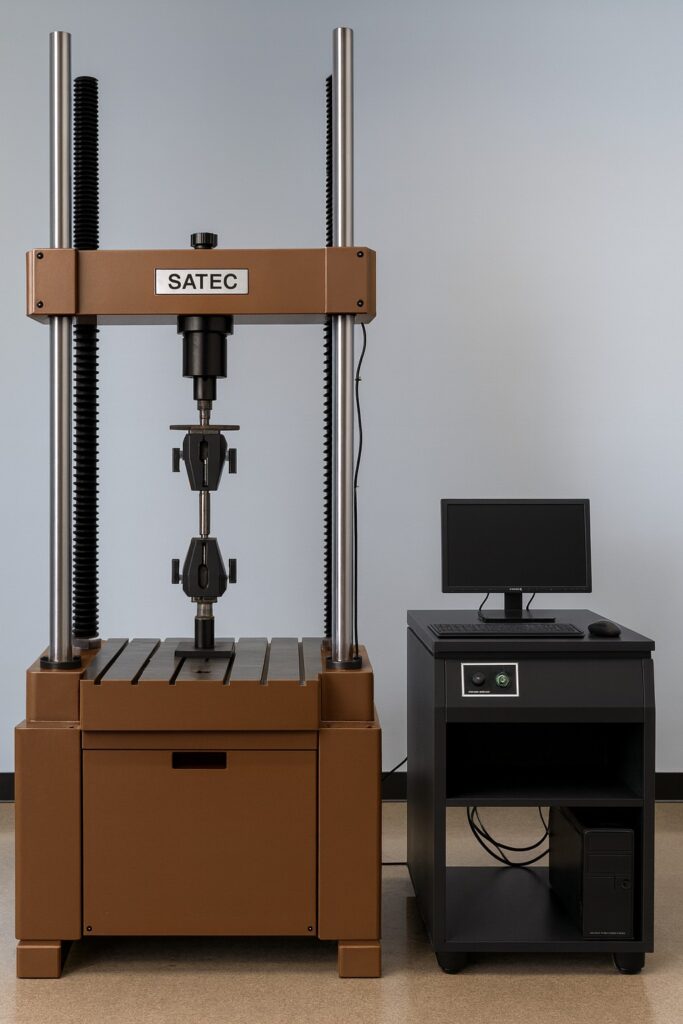

Satec Tensile Machine

Satec equipment supports tensile, compression, fastener tensile, and fatigue testing to characterize mechanical behavior across a wide range of alloy systems. Its controlled loading profiles, stabilized actuator performance, and precision measurement instrumentation enable accurate evaluation of strength, deformation response, and cyclic durability. The combination of static and fatigue capabilities provides AADFW with expanded insight into how materials perform under both immediate and repeated service stresses.

Tensile Frame System

The Instron tensile frame performs tensile, compression, fastener tensile, and fatigue testing to define mechanical response across diverse metallic materials. Controlled actuator motion, precise load application, and high-resolution strain measurement enable detailed characterization of strength, ductility, and cyclic performance. By integrating static and fatigue capabilities into a single platform, the system supports AADFW’s need for comprehensive mechanical evaluation of critical aerospace and oil & gas components.