Prove Fastener Integrity Accredited, Defensible, and Delivered Fast

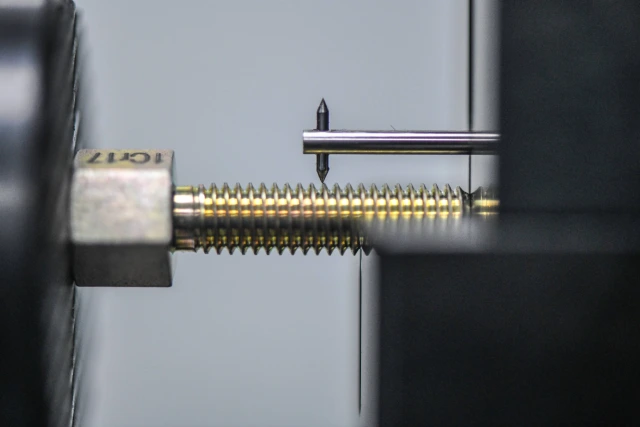

AADFW verifies the strength, ductility, threads, coatings, and microstructure of bolts, nuts, screws, studs, and pins with an integrated program of fastener mechanical & metallographic testing. We pair accredited methods, specialized fixturing, and expert metallurgists with faster turnaround than slow, global labs, so flight-critical and high-pressure assemblies keep moving.

Request a Quote Talk to a Testing Specialist : 817-540-0153

Why Fasteners Testing Matters

In airframes, engines, and pressure systems, a single nonconforming fastener can drive fatigue failures, leaks, and costly downtime. Mechanical and metallographic testing confirm property class, heat-treat condition, thread integrity, coating performance, and microstructural health, supporting conformity to drawings and specifications, reducing MRB cycle time, and safeguarding safety-critical joints.

AADFW’s Approach: Precision, Speed, and Proof

- Accredited & precise: Testing performed within an ISO/IEC 17025 quality system using calibrated equipment, uncertainty control, and audit-ready documentation.

- Faster results: Dedicated fastener fixtures, streamlined intake, and right-sized reporting compress lead times without sacrificing rigor.

- Trusted by engineers: Clear acceptance criteria, traceability to heat/lot and head markings, and metallurgical interpretations that stand up to OEM and regulatory audits.

Fasteners Testing Capabilities

Mechanical Performance (Strength, Ductility, Function)

- Tensile / Proof Load / Wedge Tensile

Confirms minimum tensile strength, yield/proof load, and head/fillet robustness under wedge loading. Typical refs: ASTM F606/F606M, NASM 1312 series, ISO 898-1.

- Axial Proof & Nut Loadability

Verifies nut performance and thread strip margins at required proof levels.

- Hardness (Rockwell/Brinell/Vickers) & Case/Core Mapping

Verifies heat-treat, carburized/nitrided case condition, and decarburization. Refs: ASTM E18/E10/E384.

- Torque–Tension / Coefficient of Friction (k-Factor)

Characterizes torque–preload relationship with lubricants/coatings and washer stacks. Refs: IFI practices.

- Prevailing Torque / Locking Performance

Evaluates all-metal and nylon-insert nuts across cycles and temperatures. Ref: ISO 2320.

Metallography & Microstructure (Quality of Manufacture)

- Macro Etch of Heads & Forgings

Reveals grain-flow orientation, laps, bursts, and forging defects.

- Microstructure & Phase Balance

Evaluates heat-treat condition, carbide morphology, retained austenite, alpha-case in Ti, delta phase in Ni alloys, tied to performance risk.

- Case Depth & Surface Conditions

Measures effective case by microhardness traverse; confirms decarburization/over-carburization per spec. Ref: ASTM E1077.

- Thread Root Examination

Polished cross-sections at first engaged thread to assess laps, seams, grinding burns, and plating intrusions.

Chemistry & Coatings (As Needed)

- Alloy Verification (OES) and interstitial control (C/S combustion, O/N/H fusion) to confirm grade and embrittlement risks.

- Coating Thickness & Integrity

Magnetic and metallographic thickness checks; adhesion and coverage at critical radii. Refs: B487, coating specs, AMS as specified.

- Hydrogen Embrittlement Support

Method selection and coordination for baking/relief verification and notched-specimen evaluation. Refs: ASTM F519, specification-driven protocols.

Documentation & Traceability

- Lot/heat trace capture; head-mark/photo documentation; calibrated equipment IDs; appendices with stress–strain curves, micrographs, and hardness maps.

Industries We Support

- Aerospace: Flight-critical fasteners, locknuts, Hi-Loks®, and specialty hardware; conformance to OEM/FAA expectations.

- Oil & Gas: Pressure boundary bolting, subsea hardware, and sour-service assemblies where hydrogen and corrosion risks are high.

- Defense & Advanced Manufacturing: Mission-critical assemblies and tooling requiring repeatable preload and documented strength.

Trusted by engineers and QC managers across mission-critical industries.

Accreditations & Standards Compliance

AADFW operates to ISO/IEC 17025 and supports Nadcap-driven program requirements using applicable industry methods, including:

- ASTM F606/F606M (mechanical testing of fasteners)

- NASM 1312 series (aerospace fastener tests, as specified)

- ASTM E18/E10/E384 (hardness) • ASTM E1077 (decarburization)

- ASTM B487/B499 (coating thickness) • ASTM F519 (hydrogen embrittlement)

- Applicable ASME/AMS/IFI and OEM specifications on request

Why Engineers Choose AADFW

- Accredited & audit-ready methods with clear uncertainty and traceability.

- Faster turnaround—specialized fixtures, efficient sequencing, and proactive updates.

- Trusted partner to aerospace and oil & gas QA organizations.

- Expert metallurgists who turn data into clear go/no-go decisions and corrective-action guidance.

Request a Quote for Fasteners Mechanical & Metallographic Testing

Confirm fastener integrity with confidence and speed. Request a Quote or Talk to a Testing Specialist : 817-540-0153 to schedule testing today.