Prove Pin, Bolt, and Rivet Performance, Accredited Results at Production Speed

AADFW performs double shear testing on aerospace and energy-sector hardware to quantify shear strength and deformation behavior of pins, bolts, rivets, and specialty fasteners. We combine ISO/IEC 17025–accredited methods, purpose-built fixtures, and expert metallurgists with faster turnaround than slow, global labs, so critical assemblies keep moving.

Request a Quote Talk to a Testing Specialist : 817-540-0153

Why Double Shear Testing Matters

In flight-critical structures and high-pressure systems, fasteners often fail in shear at joints and lugs, not just in tension. Double shear testing validates design allowables, lot conformance, and supplier quality, capturing load-at-failure and mode (shear, bearing, or mixed) on representative hardware and stack-ups. Typical applications include clevis/pin joints, hinge fittings, shear-loaded lugs, lap joints, and blind fastener installations, where verified shear capacity underpins safety, compliance, and fatigue life.

AADFW’s Approach: Precision, Speed, and Proof

- Accredited & precise: Testing within an ISO/IEC 17025 quality system using calibrated load cells, alignment-controlled fixtures, and documented uncertainty.

- Faster results: Dedicated fixturing, streamlined intake, and right-sized reporting compress lead times without compromising rigor.

- Trusted by engineers: Clear acceptance call-outs to drawing/spec requirements, photo-documented setups, and metallurgical context that withstands audits and MRB reviews.

Double Shear Testing Capabilities

- Hardware Types: Solid & tubular rivets, clevis/hinge pins, Hi-Lok®/lockbolts, bolts and studs, specialty shear fasteners, and coupons with installed hardware.

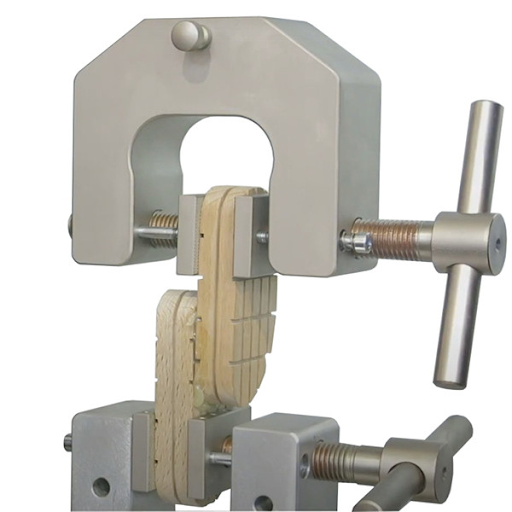

- Fixtures & Alignment: Precision double-shear blocks sized for your diameter and grip; guided loading to minimize bending; interchangeable anvils for head styles and collars.

- Measurements Reported: Ultimate shear load/strength, displacement at failure (when required), fracture mode characterization (shear/bearing/tear-out), and observation of secondary damage.

- Environments & Conditioning: Ambient testing standard; optional pre-conditioning (temperature exposure, bake/age) per spec or drawing notes.

- Installations & Stack-Ups: Testing of fasteners installed into representative materials (aluminum, titanium, nickel alloys, steels, composites with metallic backup) to evaluate joint behavior.

- Failure Documentation: High-resolution photo sets of pre-/post-test hardware and joint; optional metallography of fracture surfaces or thread/fillet regions to confirm mechanism.

- Related Evaluations (Optional):

- Tension, wedge, proof load for comprehensive mechanical characterization.

- Hardness & case depth at head/shank or thread root (macro/micro).

- Chemical analysis (OES, C/S, O/N/H) for alloy verification and embrittlement risk.

- Dye Penetrant (PT) & MAG Particle for surface-crack screening of heads, fillets, and collars

Industries We Support

- Aerospace: Shear-loaded joints in airframes, control surfaces, landing gear, and engine-adjacent hardware, aligned to OEM and FAA expectations.

- Oil & Gas: Pressure-boundary connections, valve/actuator linkages, and subsea assemblies where shear-loaded pins and bolts are common.

- Defense & Advanced Manufacturing: Mission-critical mechanisms and tooling requiring verified joint strength and repeatability.

Trusted by engineers and QC managers across mission-critical industries.

Accreditations & Standards Compliance

AADFW operates to ISO/IEC 17025 with traceable calibrations and uncertainty statements. We test to customer drawings and specifications and support common aerospace fastener practices, including NASM 1312 series (e.g., double-shear methods) and related OEM procedures. Applicable ASTM/ASME/AMS/ISO methods are followed when specified in procurement documents. Reports are audit-ready, with calibration references and setup photos included.

If your program cites a specific method (e.g., NASM 1312-13 or an OEM procedure), we’ll configure fixtures, gauges, and data capture accordingly.

Why Engineers Choose AADFW

- Accredited & audit-ready procedures, data, and images—built to satisfy primes and regulators.

- Faster turnaround with dedicated fixturing and proactive status updates.

- Trusted partner to aerospace and oil & gas QA organizations.

- Expert metallurgists who turn results into clear go/no-go decisions and practical corrective actions.

Request a Quote for Double Shear Testing

Validate shear strength with confidence and speed. Request a Quote or Talk to a Testing Specialist : 817-540-0153 to schedule double shear testing on your fasteners or assemblies today.