Accredited Shear Testing with Precision and Speed

Shear testing measures how metals and welds perform under applied shear forces, providing critical insight into joint integrity, ductility, and overall material performance.

At AADFW, we deliver accredited, precision-driven shear testing with faster turnaround times than other labs, trusted by engineers, QC managers, and compliance officers across aerospace, oil & gas, and advanced manufacturing industries.

Request a Quote Talk to a Testing Specialist : 817-540-0153

Why Shear Testing Is Critical to Structural Integrity

Ensuring Reliability, Safety, and Compliance

Shear testing evaluates how materials and joints withstand parallel stress before deformation or failure. This data is essential for:

- Safety and Performance: Confirming that welds, fasteners, and bonded joints meet load-bearing requirements.

- Compliance: Meeting ASTM A370, NASM 1312-13, ASTM E8, and ASME specifications.

- Material Validation: Comparing shear strength across alloys, weldments, and coatings for fatigue and lifecycle performance.

In industries where failure is not an option, shear testing ensures that components hold up under stress — from aircraft assemblies to subsea pipelines.

AADFW’s Accredited Approach to Shear Testing

Precision Data. Accelerated Results. Proven Expertise.

AADFW combines accredited testing methods with decades of metallurgical experience to deliver the data engineers rely on, faster than traditional testing labs.

- Accredited & Precise: Testing performed in compliance with ISO/IEC 17025, NADCAP, and FAA standards.

- Rapid Turnaround: Optimized workflows and in-house expertise shorten project timelines without compromising accuracy.

- Trusted by Engineers: Our reports meet FAA, ASTM, and ASME requirements, ensuring confidence and compliance in every result.

Shear Testing Capabilities

Comprehensive Evaluation of Welds, Alloys, and Joints

AADFW offers a full range of shear testing services for metals, welds, and bonded materials:

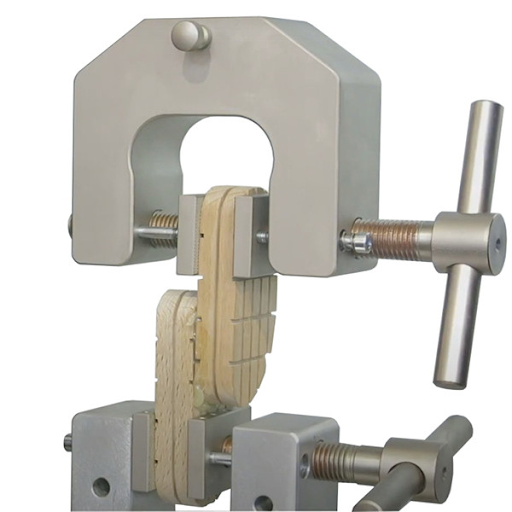

- Double Shear Testing for fasteners, pins, rivets, and bolts.

- Shear Strength Testing of Welds and Joints to assess ductility and bonding integrity.

- Lap Shear Testing (ASTM D1002) for adhesive-bonded metallic joints.

- Custom Fixturing and Test Setup for unique part geometries and specifications.

- Digital Data Capture and Analysis for precise stress-strain measurement and reporting.

Industries We Support

Shear Testing for Critical Engineering Applications

AADFW’s shear testing services are trusted by engineers and quality teams across multiple high-performance sectors:

- Aerospace: FAA/NADCAP-compliant shear testing for aircraft fasteners, weldments, and structural joints.

- Oil & Gas: Verifying shear strength of pipeline welds, subsea components, and corrosion-resistant alloys.

- Defense & Manufacturing: Ensuring structural reliability of armor plating, fabricated assemblies, and precision-machined parts.

Accreditations & Standards Compliance

Certified Testing That Meets Global Standards

All AADFW shear testing services are performed under accredited and industry-recognized methods, including:

- ISO/IEC 17025 Accredited Laboratory

- NADCAP Certified Materials Testing

- FAA-Recognized Metallurgical Processes

- ASTM A370, ASTM D1002, ASTM E8, ASME Section IX, MIL-SPEC compliance

Our results are traceable, defensible, and accepted by aerospace primes and regulatory bodies worldwide.

Why Engineers Choose AADFW

- Accredited Laboratory: ISO 17025 and NADCAP accredited.

- Fast Turnaround: Results delivered in days, not weeks.

- Expert Metallurgists: Skilled in testing complex alloys, welds, and bonded materials.

- Trusted by Industry Leaders: Confidence built on precision, accreditation, and reliability.

Request a Quote for Double Shear Testing Services

Get reliable shear strength data — fast.

Contact AADFW today to discuss your testing standards, materials, and project requirements.